Home / Design solutions / Ceiling design / What to make a ceiling from in a log house

The arrangement of ceilings in wooden buildings is slightly different from the same procedure in standard panel or brick houses. Here everything will be both simpler and more complicated. For example, it is very easy to assemble a lining ceiling in a log house or wooden house, but with plasterboard structures the situation is a little more complicated. We’ll talk about the most popular options for decorating floors in such buildings further.

Features of floors in such houses

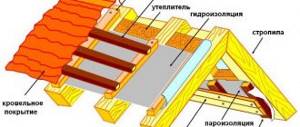

Interfloor structures in a wooden house are a complex of several components, each of which is needed to perform certain tasks. The load-bearing beams will be the basis, the decorative coating gives the surface a beautiful appearance, the insulating layer works to preserve heat in the house, and the intermediate layers of steam and waterproofing are responsible for preserving the insulation and insulating the entire structure from moisture penetration.

Based on this scheme, most of the decorative coverings are attached directly to the load-bearing parts of the floor, and only tension structures are attached to the walls. This partly makes the task easier when renovating, but there is another factor that needs to be taken into account - the shrinkage of the house. It is this that will in many cases become the determining factor when choosing what the ceiling in a wooden frame will be like.

Installation of ceilings in a log house

Wooden houses have high thermal insulation qualities. The tree can withstand the harsh northern climate.

Scheme of the installation of a hemmed wooden ceiling

An important feature of a wooden house is its ability to self-ventilate, which largely determines the choice of finishing materials. They should not interfere with this process.

Otherwise, rotting and destruction of the wood is possible, even with the use of artificial ventilation. It is not recommended, for example, to make cladding from fiberboard or plastic. This applies to both walls and ceilings. How to make your home warm and cozy?

When building a wooden house, due attention should be paid to insulation and arrangement of the ceiling. It's no secret that warm air rises, and if the ceiling in a log house is poorly made and has microcracks, then heat will escape from the premises into the attic space. This threatens not only with a decrease in temperature in the house, but also with the accumulation of condensation on the lower surface of the roof, which can lead to both damage to the roofing material itself and to rotting of the wooden elements of the rafter system.

Since about 30% of the heat leaves the house through the ceiling, it needs insulation. Mineral insulation is placed in the plane of the floor beams between the rough ceiling below and the attic floor above.

Insulation requirements:

Insulation for a wooden ceiling should be light, non-flammable and non-toxic.

- Non-flammability. For wooden houses, fire safety class “A” material is selected.

- Non-toxic. The emission of even microscopic toxic dust is not allowed.

The thickness of the material is selected individually. All cracks must be sealed before installation. If the house has several floors, then it makes sense to insulate the interfloor floors with mineral wool. Insulation will help not only save heat, but also reduce noise levels. Mineral wool has the ability to dampen high-frequency sounds. The thicker it is, the larger the range of frequencies captured. For better sound insulation, a layer of special noise-absorbing material, for example, basalt wool, is rolled out on top of it. Heavy bulk materials, such as sand, have good soundproofing qualities.

A vapor barrier film is placed under the insulation. It prevents the passage of warm, moist air currents rising from the house to the attic, and thereby protects the insulation from getting wet. On top of the insulation you need to make a waterproofing protection. When laying the film, it is important not to mix up its sides, otherwise it will lose its protective properties. The film is laid in an overlap of 10 cm and secured with tape.

The rough ceiling is laid on skull blocks, which are nailed to the sides of the floor beams. The boards for the rough ceiling are cut to a size slightly smaller than the beam span and laid closely on the tiled blocks. All wooden parts must be treated with an antiseptic. This will help prevent them from being damaged by fungal microorganisms and pests.

Design options

Taking into account the different features of such buildings and the operating conditions of the coatings, the following design methods and materials are most often used:

- Drywall. Despite the fact that the compositions assembled from it cannot be rigidly connected to the walls, there is a frame option that allows you to finish the floors even in a newly built log house - this is the so-called “floating” structure, not connected to the walls.

- Tension covering. Perhaps the most successful choice for such buildings. The elastic fabric is not susceptible to deformation and withstands various operating conditions. It is important to choose the right type of fabric used to make the coating.

- Various panels. These can be metal parts, MDF panels, and the most inexpensive plastic strips. The latter will become one of the most economical ways to decorate country houses, which is not used all year round.

- Tree. Also a very good choice for a wooden structure. There is no more environmentally friendly material and it best matches the style of the building itself. In addition, finishing can be very inexpensive if you choose affordable lining or create a composition from treated boards.

Other finishing methods can also be used, but for various reasons they will be inferior to those mentioned above, either in cost or in their characteristics.

Making a ceiling surface in a steam room from a log: all about the types of structures

There are several types of ceilings. The construction of some structures requires considerable expense and effort, while others, simpler to implement, are budget-friendly ways to build a bathhouse.

Ceiling types:

- Hemmed. Its base is wooden beams. They are used to make the ceiling. Other structural elements are attached to this base, both from the outside and from the inside. To cover the inside of the beams, use a tongue-and-groove or edged board. Layers are laid between the beams and the sheathing. First, a vapor barrier is made, then there is a layer of insulation, and then waterproofing. At the last stage, an edged board is laid on the outside of the base.

- Grazing. This type is similar to the previous one, but fewer layers are used, so it can be called an economical ceiling option. It consists of boards joined together, which should rest only on the load-bearing wall. The outside of the structure is covered with clay, then a vapor barrier layer is made and insulation is laid.

- Panel. This type is the most difficult to execute, because assembled from panel elements, which must be constructed separately, each one. The finished version of the panel is similar to a pallet with various layers and interlayers. The structure is incredibly heavy, so all layers are not laid into the ceiling at once. The outer part of this “pie” is covered with boards. The ceiling surface is supported by bars laid between the beams. On the attic side, the structure is sheathed with boards, and the walls on which the panel rests are covered with a layer of tow.

All these methods of installing a ceiling in a bathhouse differ in technology and load-bearing capacity.

Drywall

If you decide to make a ceiling from this material in a log house made of logs or beams, you should first study the diagram of a decorative design suitable for them. It differs from the standard one in the absence of a rigid connection between the frame and the walls. The frame parts are attached to the floors using standard or vibration suspensions, but nothing needs to be attached to the walls. There remains a small gap of one to two centimeters between the edge of the covering and the plane of the walls, allowing the covering to move slightly if the house changes its geometry due to shrinkage.

Calculation of the cross-section of wooden beams

The photo shows a drawing of the assembled interfloor floor.

When constructing most private houses, developers make the ceiling of the second floor from timber. This is a relatively inexpensive, but at the same time quite reliable material, which has been used for similar purposes for several centuries. The only necessary condition is the correct calculation of the cross-section of such crossbars installed in the span as joists.

To more accurately determine the cross-section of the timber for the ceiling, special formulas are used, which, among other things, take into account the resistance of the wood used and its moisture content. These parameters are defined in SNiP II-25-80, which any developer or private craftsman must be familiar with.

There you can also find the necessary formulas and tables with the help of which the parameters of beams for specific interfloor structures are determined.

When calculating wooden floors, it is also necessary to take into account the width of the span, the distance between the beams, and the shape of their section. When calculating each cross member to be laid, it must be remembered that the amount of its deflection under load should not exceed 1/250 of the span length.

Since it is quite difficult for a technically untrained person to correctly calculate the lag parameters using formulas and tables, you can use special calculators to independently select beams. It is enough to enter several basic values into such a program, and as a result, you can select the correct sizes of load-bearing joists.

Calculation of beam cross-section

The photo shows a table for selecting a beam section.

As an example, using one of these calculators, we will try to calculate which beam to use to cover 5 meters.

To enter data we need to know:

- the material from which the crossbar is made (only coniferous trees are recommended);

- span length;

- beam width;

- beam height;

- type of material (log or timber).

In order to make correct calculations, we substitute the span width equal to 5 m to the entered values, and set the beam type to timber. We will select the height and width experimentally in the parameters “dimensions of timber for floor beams”. You should definitely take into account values such as load per kg/m and the pitch between the crossbars.

For interfloor structures, the load value should not be less than 300 kg/m, since it is necessary to take into account not only the weight of furniture and people, but also the weight of the materials themselves from which the floor is made. This includes floor beams, rough and finished floors and, of course, insulation and sound insulation.

Advice. For non-residential attic structures, a load value of 200 kg/m will be quite sufficient.

Possible options

Photos of beams of different sections.

At almost all bases that sell lumber, floor timber is sold mainly in several sizes. As a rule, these are beams from 100x100 mm, to 100x250 mm, and from 150x150 mm to 150x250 mm. In order not to waste unnecessary time and money searching for logs with non-standard sizes, the price of which can be significantly higher than standard ones, we substitute into the program those parameters that are commercially available.

To do this, you must first find out from the lumber database what sizes they sell. Thus, we find that for interfloor structures the minimum size of timber should be approximately 100x250 mm, and for attic structures 100x200 mm will be sufficient, with a step between them equal to 60 cm.

If you do not trust software calculators and want to independently calculate the size of the timber for the floor, then you will have to use the formulas and tables given in the relevant technical documentation. Or you can use the general rule, which states that the height of each joist should be equal to 1/24 of the length of the opening, and its width should be equal to 5/7 of the height of the crossbar.

Stretch ceiling

This option is best suited for use in wooden houses, since the canvas is elastic and is not afraid of any deformation of the building itself. However, here you need to pay a little attention to the choice of canvas. Film ceilings cannot be installed in a log house that does not have a constant temperature regime. In other words, if the house is not heated in winter, then only textile fabric that can withstand negative temperatures can be stretched in it.

Installation of logs to log walls

Question:

Hello. It is necessary to make a floor in the finished log house, but when assembling the house there was no provision for a ledge for the logs. As a result, the lags themselves have nothing to rely on.

I read that you can cut a groove in a log, but if the groove should be 10 cm deep, then how can you then put a log in this groove? The thickness of the log is 21 cm, so do you need to cut it to half the log? Are there any other options? Is it possible to use perforated profiles for attaching joists and how reliable will this design be (how much load can be placed in kg on such a floor)?

Alexander, Novosibirsk.

Answer:

Hello, Alexander from Novosibirsk!

Another difficult question. However, in most cases they don’t ask me simple questions. It is clear that I answer all of them to the best of my competence.

The correct classic version of inserting floor joists usually consists of the following steps. In the second crown (Not the first! Since it is the main one and should not be disturbed), partial inserts are made, less often through. Into which the ends of the logs are inserted. In addition, foundation supports are installed under the logs along their length to prevent deflections. The number of them (supports) depends on the length of the lag. And they are placed at distances of approximately one and a half to two meters, depending on several factors. The main goal is to prevent sagging and so that the floors do not move around later. We had one construction company, which was headed by a man weighing a hundredweight. So, before handing over the house to the customer, he came to the site and started jumping on the floor. If the floors sagged, he was forced to redo the structure by increasing the supports, reducing the pitch of the joists, and increasing the thickness of the floor. Right up to dismantling what was done.

If a mistake was made at the start of construction, then attempts are made to eliminate what was done incorrectly. But this is associated with various assumptions, coordination and other methods that cannot always be considered sufficient.

Logs are valued as whole ones, and not as parts joined together. But it is not possible to insert a solid log into the nests of the same logs with sawing nests in them to the middle; it will simply be impossible to insert it into them.

And you have to resort to various tricks. For example, make a lag of two parts and, at the junction, mount a support column underneath it with a depth, as a rule, to the depth of soil freezing in the region. With reinforcement of the joint with various overlays on the side surfaces of the joist. The overlays are made from thick edged boards or metal strips and are about a meter or so in length. So that later there is no sagging of the floor.

Sometimes they use a rare option when they make a through cut in opposite walls (in the second crown of the log house) and insert a log in such a way and of such a length that then its ends should be flush with the outer surfaces of the logs. The operation requires quite accurately measuring the cross-sectional dimensions of the through nests and the ends of the joists themselves.

The option of fastening joists and walls with perforated corners is used, but extremely rarely. Since it is believed, and it is true, that all the loads that the floor will experience will be transmitted through fasteners. These can be self-tapping screws, wood grouse, or even just nails or staples. And this is far from a classic option. And over time, deformation and weakening of the fasteners are possible.

But in any case, it is still necessary to install additional supports for the logs according to the above option.

So look for yourself and choose something from what has been said.

Good luck!

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Other questions on the topic of gender:

- Logs thickness - table of sections of wooden logs

- The cost of replacing floors in a bathhouse - Estimate

- The floor beams of a country house sank

- Insulation of interfloor wooden floors

- What kind of film is needed to lay a floor on the ground?

- Increase the ceilings in the extension to the house from sleepers

- Pillar for attic floor beams

- Wooden floors in the garage

- Exposed beam ceiling

- Leveling floors in a log house

- Insulation of the attic floor

- Replacing an old wooden floor in a kitchen

- Interfloor ceiling in a log house

- Extension to a one-story panel house

- How to fill the underground

- Why have apartments always had wooden floors?

- Insulation of wooden interfloor ceilings

- Coating a concrete floor in a bathhouse with bitumen mastic

- Strengthening ceiling joists for the attic floor

- Floor beams for the ceiling in a garage 7 by 7 m

- Workers to replace the floor in the country house

- Harmful substances from furniture

- Sagging of the floor between the first and second floors

- Replacing joists and floors under a partition with a door

- Covering an aerated block house with a channel

- Support under the log and shrinkage of the log house

- Make a hatch in the floor to access the subfloor

- Finishing an old concrete floor on a balcony

- Replacing rotten ceiling beams

- Floor screed device

- Insulation of old floors on the balcony without removal

- Floor pie on the ground

- Replacing support posts for joists

- Overlap between the steam room and the residential floor

- Waterproofing the floor in a wooden house on the ground

- Fighting mice in insulated wooden floors

- Ceiling mats in the garage

- House with a mezzanine for children's rooms

- How to insulate wooden floors in a gas block house

- Replacing a rotten floor in a Finnish house

- Calculation of floor beams

- New floor over old wood

- How to insulate floors in a bathhouse

- Round log beam floors

- Concrete floors in a log house

- Floors without insulation in a black bathhouse

- Cost of replacing a wooden floor in a brick house

- Replacing the ceiling with increasing its height

- Leveling a sagging beam without support

- How to fix sagging wood floors

- Warm water floors in a log house

- Floor pie in the bathroom of a log house

- Replacing wood floors in a 1906 house

- Wooden floors in a house made of SIP panels

- The floor in the frame on stilts sags

- Strengthening a wooden floor

- Leveling the deflection of wooden floors

- Wooden floors are swollen

- How to change beams built into block walls

- Cladding the ceiling of an adobe house with euro clapboard

- Changing the floor in a slag-filled house

- Floor on the ground in an old wooden house

- Tiled floors in a wooden bathhouse

- Insulation of a wooden floor

- Plywood floors with joists

- How to level a subfloor under laminate

- How to strengthen a cut wooden floor beam

- Coating floor joists with bitumen primer

- How to restore old beams

- Porcelain tiles on wooden floors

- Replacing joists and subfloors in a timber house

- Ceiling beam sagged

- Repair of sagging floors in a wooden house

- Lower the floor in an old log house

- Laminate flooring in an old country house

- Compatibility of polystyrene foam and wood in construction

- Rebuilding floors in a brick house due to creaking

- Timber logs 150 x 4 meters span

- How to straighten a sagging ceiling in a house

- Replacing rotten floor joists in a log house

- Replacing floors on the ground in a bathhouse

- Waterproofing the subfloor of a house

- Beam ceiling

- The ceiling in the bathhouse turned black

- Floors made of 12 mm plywood in two layers

- New floors on old ones

- Aligning beams in a timber house

- Strengthening interfloor wooden floors

- Wooden ceiling-floor pie

- How to raise a joist without opening the floor

- Option for arranging the floor in a log house from OCB

- Is it possible to replace beams

- Interfloor wooden floors

- How to cut a block diagonally with a circular saw

- Glassine in the house floor pie

- The floors are dry - what to do?

- Repairing the ceiling of an old wooden house

- How and with what to paint OSB

- Attaching the joists to the foundation

- Waterproofing the floor on the ground

- Floating floor on the ground

- Floor pie on floor beams

- Strengthening the ceiling joist

- New ceiling without touching the old one

- Insulating the floor in a village house

- How to strengthen floor joists 150x50 span 6 meters

- Installation of floors in an extension to the house

- Wooden floors on the ground

- Cement screed on the ground

- Cold floors in the house

- Is it possible to install logs after assembling the log house?

- Section and pitch of beams for a span of 5 meters

- Re-cover the floors in a cinder-cast building

- Fastening floor joists in a log house

- Attic floor in an old cinder block house

- Channel or I-beam for floor beam

- The smell of varnish from the floor - how to get rid of it

- Floor on rotten crowns

- The floors in the country house were torn out

- How to decorate a wooden ceiling above a gas stove

- Replacing a rotten floor - price of work and material

- Floating wooden floor in the country house

- Metal I-beam as a ceiling beam

- FC plywood floors on the open terrace

- What's the best way to install wood floors on a concrete slab?

- Laminated plywood for subfloor

- The floors are rotten, what should I do?

- How to change the subfloor without dismantling the finishing floor

- Floor ventilation in a log house on a slab

- A mushroom is eating our house

- Installation of logs to log walls

- Country house made of blocks and wood

- Beam 8 meters what section

- Replacing the subfloor and flooring in a log house

- Insulation of floors with polyurethane foam in a timber house on stilts

- Ceiling joist thickness

- The floor is rotting and moldy

- DSP subfloor and insulation

- Planks for attic floors 5 m

- Replacing a beam under a brick wall

- Reconstruction of an old floor in an old house

- Exposed beam ceiling

- What to support the floor beams on

- Sandwich panel floors

- Log beams

- How to remove part of a floor beam

- Insulating the floor from the subfloor

- Cold floors in a warm brick house

- Floor installation in an old brick house

- Insulation of the floor of the 1st floor in a log house

- Soundproofing the floor of the 2nd floor in a wooden house

- I-beam wooden floor beam

- Insulating the floor in a house on stilts

- Selection of log section for a span of 5 m

- Repairing the ceiling of an old house

- Laminate flooring on the second floor in a log house

- Floor insulation in an old wooden house

- Wooden floors are worn away by a worm

- Ceiling in a wooden house

- Distance from ground to floor

- Protecting floor joists from moisture

- Wooden floor on laminate

- Strengthening wood floors

- How to lay floors in winter in a cold house

- How to replace a rotten floor

- Floor insulation

- How to strengthen floor joists

- Second floor floor beams

- Floor insulation with foam plastic

- Laying floorboards

- Channels as interfloor slabs

- Interfloor ceiling in a silicate brick house

- Chicken coop floor

- How to strengthen the ceiling of a garage basement

- Load-bearing beam 6 meters

- Moldy subfloor

- Raise floors over old floors

- Mastic for covering subfloors and joists

- How to lay plywood on floor joists

- Creaking floors in the apartment

- Floors and drainage in the bathhouse

- The logs and subfloor of the country house have rotted

- Logs 9 meters

- How to cover the first floor of a log house of 8 meters

- Rotting subfloor

- Which ceiling joists to choose

- How to put ceiling beams in a bathhouse

- Transferring beams in a log house in height

- Strengthening old wooden beams

- Covering the first floor of a house without a basement

- Insulation of wooden floors with moss

- About lumber for floors and roofs

- Strengthening or replacing ceiling joists

- Floors on the ground

- Bathroom floor tiles

- Laminate flooring in the country house

- Subfloor and roofing felt

- Replacing the support beam

- Finishing floor on old floor with insulation

- Tiled floor in a wooden house

- How to insulate the underground

- Laying parquet boards in an apartment

- What to put on the veranda floor boards

- Updating an old subfloor

- Fastening the floor joists

- Subfloor repair

- Waterproofing plank floors

- Floor beams - reinforcement

- Thickness of plywood on joists

- How to remove creaking wooden floors

- Strengthening the interfloor ceiling

- Laminated plywood for wood floor repair

- Leveling floors during house shrinkage

- Insulation of wooden floors

- Installation of floor slabs

- Attaching beams to a vertical concrete wall

- How to join three skirting boards in a corner

- Floor joist supports

- Floor beams for a span of 7 m

- Floor installation in a timber house

- How to make a floor in an extension from foam block

- Which timber to choose for a beam floor

- Repair of bath floors

- Second floor terrace floor

- Round timber floors

- How to strengthen wooden floors

- How to change a rotten beam

- Replacing floor beams in an adobe house

- Support to strengthen the beam

- Ceiling joists

- Concrete floor under laminate

- Maximum distance between floor beams

- The middle of the wooden house sank

- Repairing floors in an adobe house

- Heated floors in a wooden house

- Raise the floor in an old house above ground level

- Replacing floor joists in an old house

- Attic floor repair

- Floors - asbestos-cement pipes for pillars under logs

- Attaching joists to slabs

- Strengthening logs in a log house 7 meters long

- Bathroom floor installation

- Insulation of floors using Izospan B film

- Floor ventilation below ground level

- The floors in the timber house are rotting

- Insulation of floors on a concrete screed under linoleum

- How to make garage floors

- Types of flooring for the home

- What thickness of the floor board should be 28, 36, 40...

- Fastening floor joists in a panel house

- Concrete floor in a wooden house

- Repair of wooden floor on the balcony

- Installation of logs in a timber house

- Concrete floor screed over Sip floor

- Strengthening and insulating the floor from blocks

- How to level floor joists

- Strengthening wooden floor beams

- Should a concrete floor be connected to the house?

- Insulation of regularly flooded floors

- Insulating the floor of a house on sleepers

- How to secure floor joists over a round log

- Replacing rotten floors

- Glassine in the underground of a timber house

- The film is blowing up over the subfloor

- Questions about floors in the garage 2nd floor

- Arrangement of the subfloor in a rounded log house

- Monolithic floors on the ground

- What is the best way to cover the walls and floor of a garden house?

- How to level a concrete floor in a panel house

- How to level the floor in the kitchen

- Floor in bathhouse sink

- What to rest the floor joists on in a log house

- How to strengthen interfloor joists in a brick house

- Economical interfloor ceilings

- Insulation of concrete floors

- What is better to put under linoleum

- Subfloor repair

- Floor installation using gas silicate

- Replacing floors in a country house

- Floors made of moisture-resistant slabs

- How to lay linoleum on an old floor in an apartment

- Leveling floors in an old house

- Treatment of genital lags

- Choosing floorboards for your home

- Thermal vapor barrier in the floor pie

- Raise sagging floors without dismantling

- Thermal and sound insulation of the floor in a panel house

- The floor in the hallway of a private house is rotting

- Rotten floor in a wooden house

- How to change the floor under a fireplace

- Concrete floor in garage

- How to wax a floorboard

- How to make a wood floor in a garage

- Repair of concrete floor on the balcony

- Replacing subfloors

- Moisture-resistant laminate for wooden floors

- How to cheaply re-floor an apartment

- Bathroom sink floors

- Arrangement of rough floors

- Sagging joists and floors

- How to change a rotten floor

- How to lay the floor on a loggia correctly

- Wooden floor construction in more detail

- Subfloors made of larch on the 2nd floor

- Second floor subfloor

- How to hide air conditioner pipes in a tile floor

- Replacing a rotten floor

- Floor repair in a panel house

- Lay floors on the attic loggia

- The new wood floor has started to rot.

- Repairing a wooden floor in a country house

- How to insulate a wooden floor

- Again about floor insulation

- Larch loggia floors

- Foundation and floors of adobe house

- Floor in a finished (transportable) bathhouse

- How to arrange the floor on an open balcony

- Underfloor insulation

- Connecting the ends of the floor boards

- Concrete floor in garage

- How to level a subfloor

- How to lay a new floor on an old one

- How to lay a subfloor

- How to raise floors in your home

- How to lay floors beautifully

- Ventilation in the underground

- How to level log beams for flooring

- The subfloor beams began to rot

- Laying the floor with a board without a tenon

- Floors in a country house

- Floor on the loggia balcony

- Floors - leveling log joists

- Asbestos cement pipes to lighten concrete floors

- Insulation of underground space

- Preparing the base for laminate flooring

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services.

Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurycomfort.ru

Floors

All questions to Semenych about construction

Semenych (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topics of lumber, building materials and works, the author's opinion and knowledge of a real coven with more than 15 years of experience are provided. There is a section - funny stories of shabashniks. If you would like to receive information about this, subscribe to our website's newsletter. We guarantee that your address will not be shared with third parties.

Apartment renovation in Moscow and Moscow region

We work with a guarantee! Wide range of repair work.

Professional craftsmen. +7 (905) 797-20-34

luxurycomfort.ru

| Country house | Bath |

| For the dacha | Tool |

| Materials | Tales |

| Foundation | Log houses |

| Roofs | Insulation |

| Walls | Siding |

| Floors | Cellars |

| Attics | Doors windows |

| Stairs | Extensions |

| Wells | Toilets |

| Balconies | Loggias |

| Condensate | Flooding |

| Fences | Kennels |

| Sidewalk | Birdhouse |

| Adobe | Carts |

| Garages | Barn |

| Greenhouses | Bath |

| Swing | Brazier |

| Shower |

| Horizontal bar |

Panels

Best suited for summer cottages. There is no need for luxurious finishing and often the price of the material comes first. That is why plastic panels are great as one of the most inexpensive design options. If you choose another material - MDF or metal, the finish will be more beautiful and, accordingly, will cost more, but this design can also be used in ordinary residential buildings - it looks very decent.

What should be the height of the ceiling surface in a timber bathhouse?

Before the main work, at the planning stage, the ceiling height is selected. This parameter is important because... it determines how comfortable a person will feel in the steam room, and how much time will be spent warming up the room. In addition, the faster the required temperature is reached in a timber bath, the less fuel is consumed.

There are several factors to consider when choosing flow height.

Namely:

- The hottest place is near the ceiling. The greater the height of the room, the higher the shelves need to be placed.

- Too low ceilings are also not a good option. It is difficult to breathe in a steam room with a height of 1.5 meters or less. However, if only one person visits the bathhouse at a time, he will not feel any discomfort.

- It is necessary to choose the optimal height based on the maximum number of swimmers. Some take the height of the tallest person in the family as a basis.

The optimal ceiling height is 2 to 2.3 meters. But this does not mean that all bathhouse premises should have exactly this parameter. The steam room is the main room, wellness procedures take place here, so it is in it that you need to plan this optimal ceiling height. Other rooms in the bathhouse may be higher or lower, it all depends on how and why they will be used.

Tree

The easiest to install and very beautiful material, completely consistent with the rest of the interior, made of wood. Such a ceiling would be an ideal solution in a log house. The cost of finishing can vary from not too high to very high values if expensive wood species are used. However, this is a universal solution - for dachas you can use inexpensive lining, and in a reputable cottage the finishing made of oak or other valuable types of wood will look great.

Assembly Recommendations

Treating logs with antiseptic impregnations

When installing a subfloor in a house, it is very important to choose only high-quality strapping timber. During the operation of the coating, it will be the one that will experience the heaviest load. And if the quality of the wood or fastening is mediocre, the base can easily become deformed. In the process of assembling timber strapping, experts pay attention to the following points:

Dimensions of timber for installing logs

- The timber must be precisely calibrated and sized;

- To eliminate the possibility of wood rotting, the timber must be treated with an antiseptic;

- When assembling the frame in a frame house, it is advisable to give preference to logs made of coniferous wood (they are less hygroscopic);

- The timber frame must be laid clearly horizontally, otherwise some of the parts of the structure will experience a large load during operation;

- You can fasten the strapping logs to the support posts using clamps, metal brackets, anchors and U-shaped galvanized profiles.