Moss selection

Two varieties of mosses grow in Belarus, differing in appearance and performance characteristics: sphagnum and cuckoo flax.

Sphagnum

Sphagnum, or white moss as it is also called, is found in coniferous forests and wetlands. The plant has a long pile - green at the top and whitish at the bottom. The roots are short and unbranched (after they die they turn into peat), so collecting the tops is not difficult.

White moss is hygroscopic and not very durable. To insulate a log house, the material must be purchased with a reserve, since when it dries it greatly decreases in volume. With prolonged use, sphagnum caulk crumbles.

Kukushkin flax

It grows in the lower reaches, on forest edges, and in swamps. The plant received its name for its external resemblance to flax: it has tall reddish stems with bright inflorescences. Unlike white moss, red moss is more reliable and durable as insulation for wooden structures. It is dense, elastic, and absorbs little moisture.

Characteristics of moss and tow insulation

Moss

Moss is a natural, natural insulation material.

Characteristics: material of natural origin, which is used as insulation for log houses of wooden houses, baths, etc.

Kinds:

- swamp;

Swamp moss.

- red;

Red moss.

- hog;

This is not suddenly fallen snow, but pine forest white moss.

- sphagnum.

Sphagnum moss or sponge moss.

Properties:

- natural antiseptic;

- does not rot;

- keeps warm;

- does not interfere with natural ventilation;

- moisture resistant;

- withstands sudden changes in temperature;

- does not lend itself to fungus and mold.

Tow

Tow is a coarse, short fiber from waste production of bast crops.

Tow.

Tow for a bath comes in the following types:

- Construction is flax fiber with a length of 30–40 cm, produced mainly from hemp;

Construction tow

- Linen tow is a type of tow similar to construction, but differs in the material used.

Linen tow.

Please note: flax tow has the lowest thermal conductivity. Out of 50% moisture, it absorbs only 8%, when the figure for other representatives is 13%.

- Ribbon is linen ribbons of various widths.

Tape tow.

Note: the advantages remain with the tape type, since the longitudinal structure of the fiber is preserved during production, which allows you to manipulate the thickness and width of the compacted seam.

- Linen felt is presented in the form of a canvas.

Linen felt.

- Jute tow is an analogue of flax, made from the jute bush.

Jute tow.

General properties:

- high environmental indicator;

- water resistance;

- thermal insulation;

- sound insulation;

- moisture resistance.

Pros and cons of moss insulation

Construction moss for log houses is more effective compared to another natural material - tow. It is impossible to evenly fill the gaps between the crowns, which is why the tree wears out faster under the influence of external factors. Tow is often pulled out by birds and small rodents to make nesting sites.

Moss is preferable in the construction of log houses due to a number of advantages over other insulation materials:

- thanks to the long fibers, it is easily collected into dense bundles and is convenient to work with;

- environmentally friendly, does not contain toxic additives, smells pleasant;

- due to the antiseptic component (sphagnol), it protects the tree from parasitic organisms;

- absorbs moisture well and quickly evaporates it when wet, preventing the appearance of fungus and rotting of logs;

- retains heat well and at the same time provides air exchange to the walls.

Moss also has its drawbacks. It is difficult to find it on the open market, and collecting and drying it yourself is a rather labor-intensive process.

How to lay moss correctly

Dried and then soaked moss acquires additional strength. It is easier to lay and tuck. It is not blown away by the wind. So. After finishing the fitting of the logs, the moss is evenly laid out crosswise, in a layer of 4 - 5 cm, with a laying width of 20-25 cm. Should the moss be compacted during inter-crown installation and how much? Masters disagree, but when comparing methods, I chose the most rational one for myself. It will be sufficient to press the layer of moss with your palm, thereby simultaneously detecting foreign inclusions (cones, knots). The same layer is placed in the bowl, making sure that the fibers protrude beyond its limits. In order not to move the layer of compacting moss, it is advisable to lay the next log together, carefully lifting it over the bowl. But even the most careful inter-crown placement of moss is not 100% successful. There is also an important procedure, or rather a stage in construction, which will ensure a comfortable microclimate of a log house. The work is not difficult, but it requires painstaking work - caulking a log house.

Preparing moss for interventional insulation

The quality of thermal insulation largely depends on the conditions of raw material procurement. Both types of moss are collected in the fall, when there are not many snails and insects in the plant material.

- For sphagnum, the optimal collection time is a clear sunny day. When moisture is lost, its thermal insulation properties do not deteriorate, so it is not afraid of bright rays.

- It is advisable to collect red moss for log houses in cloudy weather, as it is sensitive to ultraviolet radiation. It is better to harvest raw materials not in a swamp, but in a forest area, under trees: there the moss is less wet and dries out faster in the future.

Baths made of timber

A bathhouse built from timber is also environmentally friendly, but only in addition to laminated timber. Walls made of profiled and laminated timber do not require additional processing. And internal and external finishing should be done for baths from edged and unplaned timber. The foundation for the construction of a timber bathhouse can be built lightweight, because the material itself and the structure made from it are light in weight. You can assemble a bathhouse from timber in a short time. Caulking and insulation work must be carried out for the walls of the bathhouse made of edged timber. But planed, edged and profiled structures do not need additional insulation. It is better not to use laminated veneer lumber for the construction of a bathhouse, because... it may not withstand high temperatures or temperature changes and may crack.

It is advisable to build baths from wooden materials, not brick. After all, wood breathes, thereby constantly circulating air and regulating the microclimate in the room. They mainly use coniferous trees, and when heated, they release substances into the air that are beneficial for the respiratory system and the entire body as a whole. Of all the materials, the most profitable construction of a bathhouse is carried out using rounded logs and profiled timber.

A real Russian bathhouse is a home “center” where you can improve your health. However, everyone knows that a sauna requires high temperatures, to achieve which a lot of fuel is spent, and, therefore, your money. Therefore, even at the time of construction, the issue of insulating a wooden structure should be carefully considered.

As for the process of insulating a bathhouse, its beginning must necessarily be based on the choice of inter-crown insulation , the best options for which are moss and jute tow. Actually, we will talk about which of the listed materials is better for us to choose in this article.

Rules for drying building moss

To prevent the collected moss from becoming moldy, it is sifted to remove soil, leaves and foreign plants are selected. After this, the material dries naturally within 1-3 weeks, depending on the degree of humidity.

- For drying, Kukushkin flax is laid out in a continuous strip on any base. Ready-made red moss is laid as roll-type insulation between the crowns of the log house.

- Sphagnum is placed in small bunches so as not to disturb its fragile structure.

If the drying technology is followed, the dry moss curls into a rope, but does not break. The finished insulation is collected in bags.

How to caulk a bathhouse correctly and when to do it

Putting up a log house from a log or timber is not the whole task. It is also necessary to properly caulk this log house: to seal the gaps between the crowns and the cracks that form when the wood dries out. This is done so that the log house of the bathhouse loses as little heat as possible. The quality of the log house's assembly is determined by how the crowns are laid. It is important not only to cut out the bowls and grooves correctly, but also to lay inter-crown insulation between two rows of logs or beams.

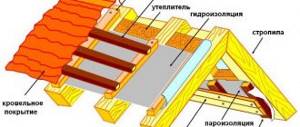

The insulation is installed during the assembly stage of the log house

What it will be - moss, tow or jute - is up to you, but such a layer must be present. When building a log house, you need to lay insulation in two layers:

- on the lower crown so that the edges of the insulation protrude beyond the edges of the bowl by 3-5 cm, the width of the insulation, in general, is taken 5-10 cm more than the width of the bowl;

- Insulation is also placed in the bowl of the upper crown; its edges protrude beyond the bowl by 3-5 cm.

Please note that when using moss or tow, there is no need to “tap” the material. When tapped with a hammer or an ax butt, the moss fibers break and dents form on the wood, which are directed across the fibers. Such damage can lead, in the future, to the development of foci of rotting. It is enough to simply compact the fibers with the palm of your hand, leveling and probing the layer; if you come across large foreign objects (cones or sticks are often found in moss), simply remove them.

Laying moss when assembling a log house

When using tape insulation, you can fix it using a construction stapler - damage to the wood from the staples is minimal, and the material is held securely. It is advisable for two people to lay the “insulated” crowns so that they can take the log from both ends and lower it so as not to move the insulation.

How to caulk a log bathhouse

All materials for caulking can be divided into two main categories: natural (tow, hemp, moss, jute, etc.) and industrial sealants. Sealants are applied faster and easier to work with. Usually, to reduce the consumption of sealant, a cord is placed in the gap between the rims, and only then a sealant is applied on top of it, which, when wet, is leveled with a special spatula.

When caulking, it is not appropriate to have a spatula-scalpel at hand. The working part of the tool is made of hardened carbon steel

Synthetic sealants have a number of disadvantages:

- some of them do not tolerate exposure to ultraviolet radiation - when irradiated, they lose their properties, crumble and are blown away by the winds. The problem is solved by strengthening strips that will cover the seams from ultraviolet radiation;

- Some sealants for log houses, when dry, form a monolith, which, when wood expands/contracts (depending on weather conditions), interferes with the process and contributes to the destruction of adjacent wood fibers. For this reason, it makes sense to use flexible sealants.

Elastic joint sealant for wood from EUROTEX

The video shows how to use Eurotex sealant.

As shown in the video above, you can use a regular tablespoon as a tool to level and remove excess sealant.

If you decide to use one of the sealants, carefully read the instructions and description, make sure that it is compatible with the type of wood from which the log house is built, can be used in your region (temperature regime) and has the necessary qualities.

The use of sealant is justified in the case when it is used to seal caulked cracks: after caulking the log house twice with tow, moss or jute, wait for the log house to completely shrink and acquire operational dimensions, after which a cord is laid in the seams, and then the sealant is applied.

Natural materials for caulking also have their advantages and disadvantages, in addition, each of them requires certain preparation.

Moss

The most proven material for caulking a bathhouse is moss. It has been used for centuries. Today, many other materials have appeared, but they have not surpassed moss in terms of characteristics. It is more convenient to work with new materials (especially tape materials). This is undeniable, but the qualities of moss remained unattainable for them. Chief among them is the ability to resist bacteria and high resistance to rotting.

Not aesthetically pleasing, but practical

The moss is first dried and then wetted again before use. This restores elasticity to the stems. The soaked moss is laid out in an even layer so that its ends hang down on both sides of the log/beam. After completing the collection of the log house, too long stems of moss are trimmed, everything else is tucked in and tucked into the cracks of the log house - the initial caulking of the log house is performed. This is followed, after six months and after a year and a half, by repeated caulking.

Jute

Jute is increasingly being used in the construction of wooden bathhouses and houses. And not just jute fibers, but rolled material. Jute fiber has good characteristics: it has good heat-insulating properties, due to the large amount of lignin - a natural resin that serves as a binding element - it is practically not subject to rotting and has low hygroscopicity. Even at high humidity, jute remains dry to the touch.

Jute insulation can be of several types:

- Jute tow. When making this material, the fibers are not torn, but combed, giving them the required direction. With this processing, jute retains its properties to the maximum extent. But such material is inconvenient for caulking: it is hard and not dense enough, working with it is quite difficult, caulking has to be done several times: firstly, the birds pull the fiber into nests (the material is natural), secondly, it shrinks and becomes compacted ( due to the rigidity, it is not possible to immediately achieve the required seam density in one go).

Jute tow

- Jute felt. This is a material consisting of 90% torn jute fibers and 10% long flax fibers. The material is dense and flexible at the same time. It is much easier to work with, but if the fibers are not long enough, it tends to clump and fall out. When choosing jute for caulking, pay attention to the length of the fibers - only fibers longer than 2 cm will provide the required elasticity. Material made from shorter fibers will become denser and lose most of its properties, and short fibers will simply spill out or be blown away by the winds. Another disadvantage is that this material often becomes a breeding ground for moths. Therefore, before use, it is advisable to treat it with impregnation against moths and rot.

Jute for baths - jute felt

- Flax-jute . A combined tape material consisting of half soft flax fibers and half hard jute fibers. This combination attracts many builders, but this material is prone to rot and is often attacked by moths. So, just like jute felt, flax-jute requires treatment against rotting and moths before use.

Tow

Tow is waste that is generated during the primary processing of natural fibers. For caulking log houses, tow made from jute, hemp and flax is used. The characteristics of the material and its quality depend on the source raw materials, the degree of purification of the fibers and their length. Construction tow is pressed into square blocks. To use when caulking a log house, a strip of material is pulled out from a common block, twisted into a rope and placed in the seam. Combed tow, which is sold in rolls, is more convenient to use.

Tow for a bath

It is inconvenient to work with such material: it is difficult to achieve a uniform layer when used as inter-crown insulation, and for caulking a log house, tow is excessively rigid, which is why it is almost impossible to achieve a dense filling of the seam the first time and you have to periodically re-caulk it. If the choice is between moss and jute tow, then we can definitely say that moss is better for a bath - it has the ability to inhibit the development of putrefactive bacteria and fungi.

When to caulk a bathhouse

The log house is assembled, when is the first time you can caulk a fresh log bathhouse? If the log house was assembled using moss or tow, then remnants of material of different lengths stick out between the crowns. In this case, you can perform the initial caulking immediately: trim the overly long fibers, tuck them inward and tuck them into the seams. There is no need to be zealous about this. This is preliminary work, the purpose of which is to remove fibers. But this must be done following the rules of caulking. If the log house is assembled on tape insulation, nothing needs to be done.

Bath after initial caulking

The first “serious” caulking is carried out approximately six months after the collection of the log house. During this time, the logs/beams will lose most of the excess moisture, new cracks will appear, the crowns and corners will basically “sit” in place. At this time, the first caulking is carried out. After this process, you can install doors/windows.

A second caulk will be needed about a year after the first. A year and a half has passed since the construction of the log house, the log house has become stable. Now all seams and cracks are checked, all defects are eliminated. Depending on the material and quality of work, it may be necessary, in another five years, to caulk the seams again. But there have been cases (usually this is the result of the work of “shabashniks”) when caulking errors are corrected for several years in a row. Most often, this need arises if the log house was built without inter-crown insulation.

How much tow do you need for a bath?

Any natural material for caulking is compressed many times during installation and a large amount of it can fit into a log house, even with good inter-crown insulation. No one can say exactly how much tow is needed for a bathhouse: it also depends on what material the log house is assembled from and how the grooves are cut out in the logs. When manually cutting grooves, as a rule, more material is wasted. Also, a sanded log requires more material compared to a rounded one. Less is required for a log house, but even here the amount of tow or moss that will be used to seal the cracks depends on the accuracy of the geometry of the beam and the depth/number of cracks that appear during drying.

Caulking rules

Caulking a log house is not a very difficult task, but it is long and tedious. Everything needs to be done thoroughly and slowly, so it takes a lot of time - it took 10 days to caulk a small 5*4 bathhouse (one worked for 7-8 hours).

The main thing is not to overdo it in the efforts made when hammering in the insulation, which can lead to the log house rising by 15 cm or more.

Rules for caulking a log house:

- You need to start from the bottom crown, moving along the entire perimeter, first from the outside of the building, then caulk the same crown from the inside. And only after that start processing the next crown.

- When caulking, pay special attention to the corners - these are often where the most significant gaps are located.

- During primary caulking, you first need to pick up the hanging material, bend it down and tuck it into the gap. The tool should be used as needed. Perform this operation on a section about a meter long, then move on to the next section.

- In the same area, use caulk and a wooden mallet (sometimes a hammer is used, but the mallet does not knock off your hands so much) to compact the material. You need to hit the caulk until the material begins to spring back. Then move on to the next section.

- After compaction, a gap formed. A piece of insulation is again placed in it. If it is tow, you need to roll it into a rope of the required thickness or tear off a piece of the required length from the tape. This piece is also hammered with caulk and a mallet until a springy effect appears. Repeat this operation until the gap is completely filled and move on to the next section.

Like every business, caulking requires certain skills. Since there will be more than one such procedure, you will eventually gain skills. As you gain experience, you will notice the mistakes that you made at the beginning of your activity - this will be your chance to eliminate them. Actually, it is not the gods who burn the pots, but it is possible to caulk a log house more or less efficiently even if you have no experience.

baniwood.ru>

Laying insulation when assembling a log house

To make the dried material more pliable and easier to take the shape of the groove, after unpacking it is folded into a stack and periodically sprayed with water from a sprayer for two days. Caulking a log house with moss has its own characteristics, taking into account the type of plant material.

- Bunches of sphagnum are carefully fluffed with your hands and given the consistency of cotton wool. Next, the white moss is evenly distributed over the crown, placing the stems perpendicular to the logs.

- Each subsequent bunch is laid with an overlap in relation to the previous one, so that the row is dense.

- Ribbons of red moss are laid across the logs, also maintaining overlap.

- The layer thickness should be at least 10-15 cm.

- At the joints of the logs, the insulation is installed, extending it along the edge by 40 mm, and between the tiers the moss should hang down by at least 10 mm. Subsequently, the edges are folded and the seams are sealed.

Moss

Photo: Cuckoo flax moss is most often used for the construction of baths. This is one of the best options when choosing inter-crown insulation.

In the process of insulating wooden houses and bathhouses, moss has been used for a very long time. At the same time, today only two varieties of moss are known and most relevant, which can be used in construction. Their names: cuckoo flax and sphagnum moss. Externally, they differ in color, feel different to the touch, and differ in the structure of the petals. However, they have one common and very important operational property - they can be an antiseptic for lumber.

Photo: sphagnum moss is also used to build baths

Actually, antiseptic properties mean, first of all, the protection of wood from the effects of harmful microorganisms, which can lead to the complete destruction of lumber, teak and its darkening, which will make the tree unattractive. Note that sphagnum moss has a greater antiseptic effect. This is the so-called white moss, which is laid on each subsequent and previous crown of a wooden house in a correctly selected layer. To be honest, it can be difficult to choose the thickness of moss, since this requires some experience.

In turn, cuckoo flax also has an antiseptic effect, but in a slightly lesser form. However, it tolerates moisture well, which allows it to be used no less than a wooden house will serve. Note that this insulation has its antibacterial effect due to the sap that it releases onto the surface of the tree when it is pressed by the upper crown of a wooden house. By the way, it is for this reason that cuckoo flax and sphagnum moss should only be laid when wet.

As practice shows, this type of insulation requires additional protection using a sealant. In addition, at the time of laying it cannot be released outside, since everything that “sticks out” from the crowns of a wooden house will be stolen by birds to build nests. This means that after the wooden structure shrinks, we will have to caulk the walls using already dry moss or another type of insulation.

Advantages of interventional insulation – moss:

- unique environmental qualities;

- high heat-protective qualities;

- excellent antiseptic protection of inter-crown grooves (sutures);

- a unique forest smell inside the bathhouse;

- durability.

Sphagnum moss. Application in construction

From a biological point of view, sphagnum moss is considered a unique plant that completely lacks roots. Since ancient times, people have tried to use it in everyday life for various purposes. Thanks to its beneficial properties, moss has found application in such areas of life as medicine, beekeeping, construction, crop production, etc.

It is known that this plant contains carbolic acid, which acts as an antiseptic and destroys microbes harmful to moss. This feature of moss began to be used in construction: wood logs were covered with moss so that they were not affected by fungus.

And if, for example, you disassemble an old wooden house, you can see that there are no traces of fungus formation on the timber. Such a plant can also protect wooden crowns from rotting, germs and mold.

The space between tree crowns is also covered with moss. In addition to building houses, it is also used to build baths or saunas. In the second option, preference is given most to moss since it has the properties of a sponge or, scientifically, hygroscopicity.

By the way, if translated from Latin, sphagnum will mean “sponge.” Therefore, this plant was so named, since it is capable of absorbing moisture whose volume exceeds its own by 20 times. In addition, the rather small volume of moss allows it to be laid between the crowns of a house under construction.

This natural material has gained particular popularity in the construction of various rooms with high levels of humidity. Thus, baths built using moss serve reliably for many years without visible rotting processes.

Warming qualities.

In addition, sphagnum moss is often used as an effective heat insulator. If you correctly place the moss in the space between the logs and crowns, then you don’t have to worry about holes appearing in these places.

Sphagnum moss has a unique forest aroma. With its help, the walls of the building are able to breathe. This way the air in the room will always be clean, fresh and pleasant. The unique qualities of moss have a beneficial effect on the interior atmosphere of the room and relieve it from the negative effects of harmful bacteria.

To the above-described properties of natural material, you can also add several more positive characteristics. Being a natural product, moss is impeccably environmentally friendly and has a long service life. The material does not decompose under the influence of high and low temperatures. It is easy and simple to use. In addition, it ranks first in terms of availability in our country. It is also not difficult to find masters who know all the secrets of its use.

Considering all the positive qualities of moss, it is worth noting that its use is not limited to the construction sector. It is also actively used in crop production and medicine. In peaty areas you can find a huge mass of moss stems, which are used to generate energy. Or they can be used as a means to fertilize fertile land.

However, despite all the positive aspects of this material, it still has a number of disadvantages. This concerns its use in construction, namely its use as insulation.

The fact is that, filling the voids between the crowns, the moss dries out over time and cracks form in these places. Therefore, new layers need to be laid from time to time. Another disadvantage is that once the moss dries out it becomes brittle. And when laying a new layer, certain skills are required so as not to damage existing ones.